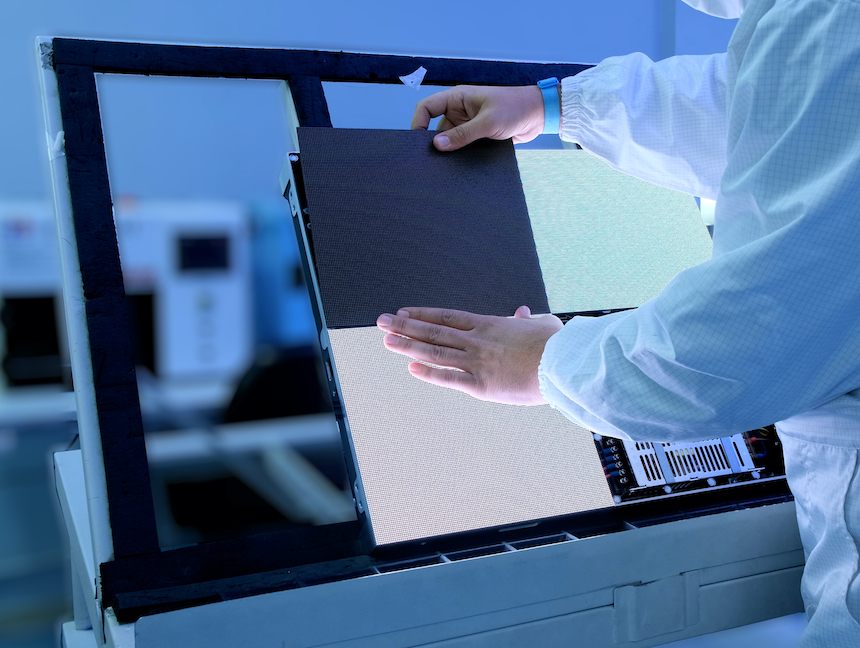

VISUAL ELECTRONICS REPAIR

FEBA provides after-sales technical service for all equipment with LCD, LED, MicroLED and TFT panel technology.

MECHANICALS REPAIR

FEBA manages the repair, adjustment, calibration, full refurbishment processes of all mechanical devices in IT, bank equipment and retail equipment.

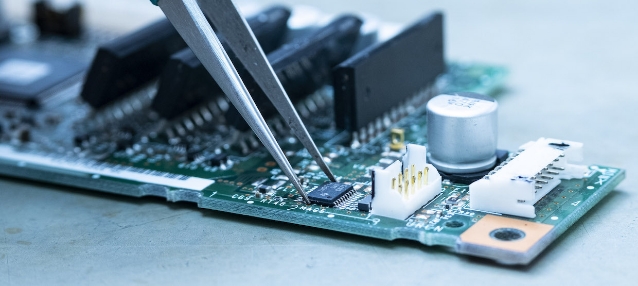

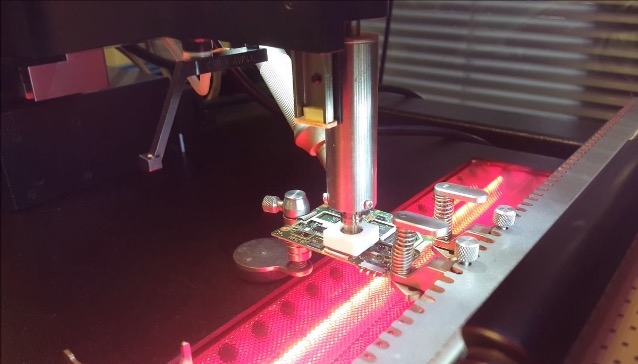

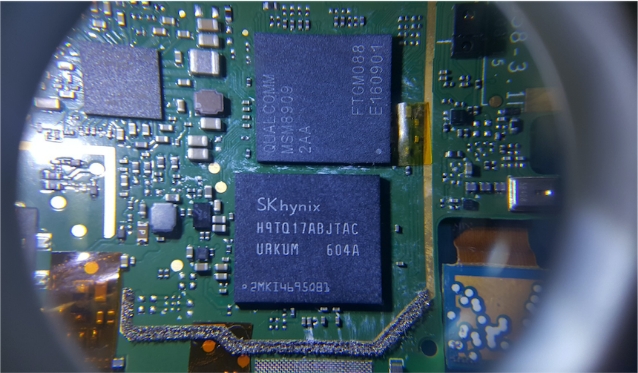

ELECTRONICS REPAIR

From SMD & BGA Component Level repair to full refurbishment, FEBA provides high-volume repair service for all electronic products to IPC 7711/7721 standards.

OTHER SERVICES

Setting out with an environmentally-concious approach, FEBA prevents electronic waste by renewing spare parts and products that are replaced after sales.